In the world of machining and fabrication, where precision is paramount, the die grinder stands out as a versatile and indispensable tool. Whether in metalworking, woodworking, or automotive industries, die grinders excel in intricate shaping, deburring, polishing, and grinding tasks. At the heart of their efficiency lies the humble yet mighty grinding wheel. Let’s delve into the world of grinding wheels for die grinders and explore how they elevate precision to an art form.

The Backbone of Die Grinding: Grinding Wheels

A die grinder, a handheld power tool reminiscent of its larger cousins, the angle grinder, and the bench grinder, relies heavily on its grinding wheels for performance. These grinding wheels, specifically designed for die grinders, come in various shapes, sizes, and compositions to cater to a myriad of tasks. From removing excess material to achieving fine finishes, the right grinding wheel can make all the difference in the outcome of a project.

Versatility in Action

One of the defining features of die grinders is their versatility, and the same applies to the grinding wheels they use. These wheels are crafted to tackle a wide array of materials, including metals, plastics, wood, and composites, making die grinders indispensable across diverse industries.

For metalworking applications, grinding wheels with abrasive materials like aluminum oxide, silicon carbide, or ceramic grains excel in shaping, deburring, and smoothing metal surfaces with precision and efficiency. Woodworkers benefit from grinding wheels with coarser grits for shaping and finer grits for polishing and finishing delicate woodwork.

Shapes and Sizes Matter

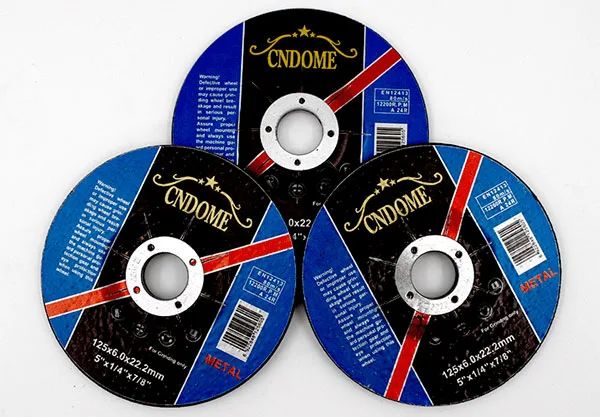

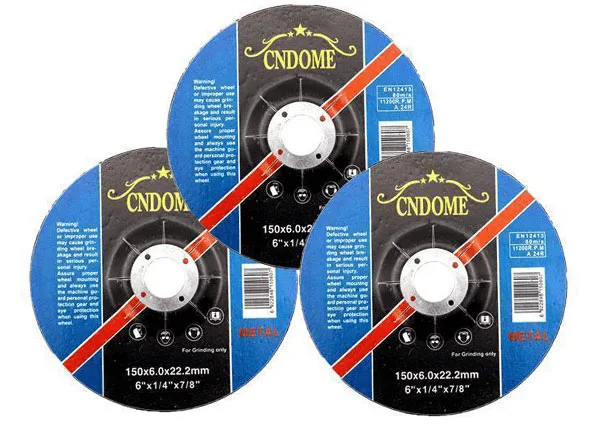

Grinding wheels for die grinders come in various shapes and sizes, each tailored to specific tasks. From cylindrical wheels for grinding and deburring to cone-shaped and tapered wheels for intricate detailing, the diversity in wheel shapes empowers craftsmen to tackle intricate work with ease and finesse.

Additionally, the diameter and thickness of grinding wheels play a crucial role in their performance. Smaller diameter wheels offer better maneuverability in tight spaces, while larger wheels provide more surface area coverage for rapid material removal. Balancing size considerations with the intricacies of the task at hand is key to maximizing the die grinder’s potential.

The Quest for Quality: Material Composition

The composition of grinding wheels significantly impacts their performance and longevity. Manufacturers employ a range of abrasive materials, bonding agents, and reinforcement structures to tailor grinding wheels to specific applications.

For heavy-duty tasks that demand durability and aggressive material removal, grinding wheels with reinforced fiberglass mesh or resin bonding excel. Conversely, for precision work requiring smooth finishes and minimal material loss, finer-grit wheels with ceramic or diamond abrasives provide the necessary finesse.

Conclusion

In the realm of precision machining and fabrication, die grinders and their trusty grinding wheels stand as symbols of craftsmanship and efficiency. From shaping and deburring to polishing and finishing, these dynamic duos elevate ordinary materials into works of art with unparalleled precision and finesse. By understanding the intricacies of grinding wheels for die grinders, craftsmen unlock a world of possibilities, where every stroke of the wheel is a testament to mastery and precision.