In the world of metalworking and fabrication, the right tools can make a significant difference in both the quality of the work and the efficiency of the process. One such essential tool is the cut-off wheel. Specifically, 4.5″ cut-off wheels with a 5/8″ arbor have become a popular choice for many professionals due to their versatility and performance. In this blog, we will explore the benefits, applications, and best practices for using these cut-off wheels.

What is a 4.5″ Cut-Off Wheel with a 5/8″ Arbor?

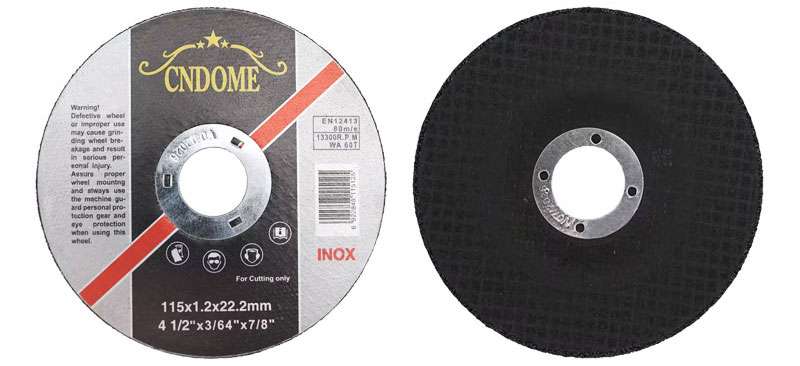

A 4.5″ cut-off wheel is a thin, abrasive disc designed for cutting through various materials, particularly metals. The 5/8″ arbor refers to the diameter of the hole in the center of the wheel, which fits onto the spindle of the angle grinder or cut-off tool. This standard size ensures compatibility with a wide range of machines, making it a convenient choice for many users.

Benefits of Using 4.5″ Cut-Off Wheels

- Versatility: These wheels can cut through a variety of materials, including stainless steel, carbon steel, aluminum, and other non-ferrous metals. This versatility makes them an essential tool in many workshops.

- Precision: The thin profile of cut-off wheels allows for precise cuts with minimal material waste. This precision is particularly important in applications where accuracy is crucial.

- Speed: Cut-off wheels are designed to cut quickly and efficiently, reducing the time required for each task. This efficiency can significantly improve productivity in a busy workshop.

- Ease of Use: With the standard 5/8″ arbor size, these wheels are easy to install and remove, allowing for quick changes between tasks.

Applications

4.5″ cut-off wheels with a 5/8″ arbor are widely used in various industries, including:

- Metal Fabrication: Cutting metal sheets, pipes, and rods to size.

- Construction: Cutting rebar, steel beams, and other structural elements.

- Automotive Repair: Removing damaged parts and cutting through metal components.

- DIY Projects: Handy for home improvement tasks involving metal cutting.

Best Practices for Using Cut-Off Wheels

- Safety First: Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection. Ensure that your work area is well-ventilated to avoid inhaling dust and fumes.

- Correct Installation: Make sure the cut-off wheel is securely fastened to the grinder or cut-off tool. Check for any cracks or damage to the wheel before use.

- Proper Technique: Hold the grinder with both hands and maintain a steady grip. Let the tool do the work; do not apply excessive pressure, as this can cause the wheel to wear out faster and increase the risk of accidents.

- Wheel Selection: Choose the right cut-off wheel for the material you are working with. Different materials require different abrasive compositions for optimal performance.

- Regular Maintenance: Inspect your tools and wheels regularly for signs of wear and tear. Replace worn-out wheels promptly to ensure consistent performance and safety.

Conclusion

4.5″ cut-off wheels with a 5/8″ arbor are a valuable addition to any metalworking toolkit. Their versatility, precision, and efficiency make them an ideal choice for a wide range of applications. By following best practices and prioritizing safety, you can maximize the benefits of these wheels and achieve outstanding results in your projects. Whether you’re a professional metalworker or a DIY enthusiast, investing in quality cut-off wheels will undoubtedly enhance your cutting capabilities.