Shipyards are bustling hubs of industrial activity where precision, efficiency, and safety are crucial. Whether it’s cutting through thick steel plates, trimming pipes, or preparing metal for welding, the right cutting wheel can make all the difference. This guide will explore the importance of shipyard cutting wheels, their key features, and how to select the right one for your needs.

The Role of Cutting Wheels in Shipyards

Shipyards demand tools that can handle heavy-duty cutting tasks on tough materials like steel, aluminum, and other alloys. Cutting wheels are essential for tasks such as:

- Steel Plate Cutting: Preparing large steel sheets for hull construction.

- Pipe and Tube Cutting: Trimming pipes to precise lengths for plumbing and structural components.

- Weld Seam Removal: Cleaning up welded joints to ensure smooth finishes.

- Maintenance and Repairs: Cutting through rusted or damaged metal parts during ship repairs.

Key Features of Cutting Wheels for Shipyards

Cutting wheels designed for shipyard use must offer:

- High Durability

The abrasive material and bonding agents need to withstand the high pressure and continuous use typical in shipyards. Look for wheels made from high-quality aluminum oxide or zirconia. - Thin and Precise Cuts

Thin cutting wheels provide precise and clean cuts, which are essential for minimizing material waste and ensuring perfect fits during assembly. - Compatibility with Heavy-Duty Equipment

Shipyard cutting wheels are often used with industrial grinders and cutting machines. Ensure the wheel size and arbor fit your equipment specifications. - Corrosion Resistance

Working near the sea exposes tools to moisture and salt, making corrosion-resistant wheels a necessity. - Safety Standards Compliance

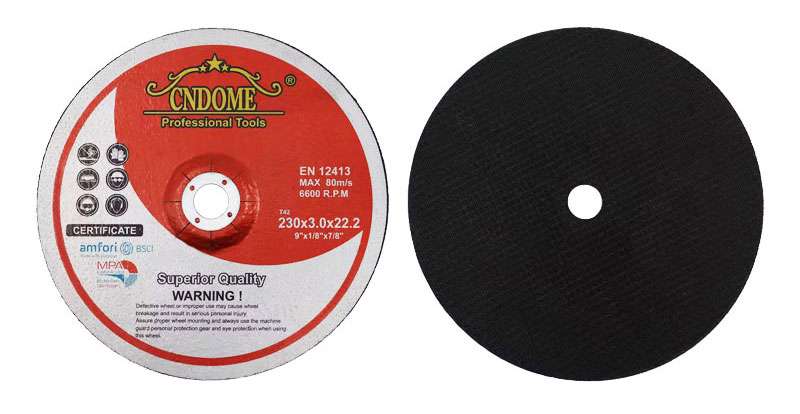

Always select cutting wheels that meet international safety standards (e.g., EN 12413) to protect workers from potential hazards.

Common Materials Used for Shipyard Cutting Wheels

- Aluminum Oxide: Great for cutting steel and general-purpose applications.

- Zirconia Alumina: Provides enhanced durability and is suitable for tougher materials like stainless steel.

- Silicon Carbide: Ideal for non-ferrous metals like aluminum and brass.

Selecting the Right Cutting Wheel

Here are a few considerations when choosing a cutting wheel for shipyard applications:

- Material Type: Match the wheel to the material being cut (e.g., use zirconia for stainless steel and aluminum oxide for carbon steel).

- Wheel Thickness: Thinner wheels are better for precision cuts, while thicker wheels handle heavy-duty cutting tasks.

- Speed Rating: Ensure the wheel’s RPM rating exceeds the grinder’s speed to prevent breakage.

- Size: Select a wheel size compatible with your grinder (common sizes include 4.5”, 7”, and 9”).

Applications and Use Cases

- Shipbuilding: Cutting steel panels for hulls or superstructures.

- Maintenance: Trimming pipes and metal parts for repairs.

- Decommissioning: Dismantling old ships into smaller, manageable pieces.

Tips for Maximizing Cutting Wheel Performance

- Use the correct wheel for each task.

- Avoid excessive pressure to prevent premature wear.

- Inspect wheels regularly for cracks or damage.

- Store wheels in a dry, clean environment to avoid moisture absorption.

Final Thoughts

Investing in high-quality cutting wheels designed for shipyard use is essential for achieving efficient, precise, and safe results. By selecting the right tools, you can streamline operations, reduce material waste, and ensure a safe working environment for your team.

Looking for premium cutting wheels for shipyards? Contact us today to learn more about our durable and high-performance products!