In the world of manufacturing and metalworking, grinding wheels are indispensable. These tools are used for a variety of purposes, from sharpening tools to smoothing surfaces. Importing grinding wheels can be a lucrative venture, but it requires careful planning and knowledge of both the product and the import process. This guide aims to provide a comprehensive overview of everything you need to know about importing grinding wheels, including market analysis, supplier selection, import regulations, and best practices.

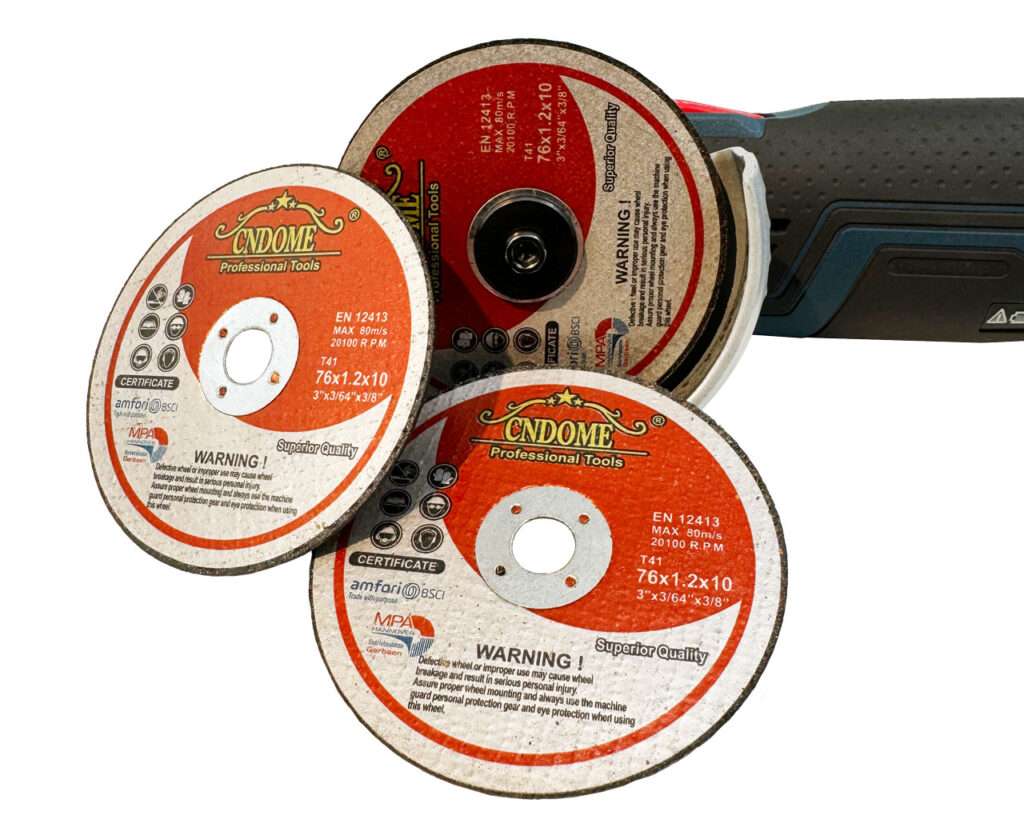

Understanding Grinding Wheels

Types of Grinding Wheels:

1. Straight Grinding Wheels – Commonly used for surface grinding.

2. Cylinder or Wheel Ring – Used for producing flat surfaces.

3. Tapered Grinding Wheels – Designed for grinding threads.

4. Straight Cup – Ideal for grinding tools like chisels.

5. Dish Cup – Used in tool and cutter grinders.

6. Diamond Wheels – Best for cutting and grinding hard materials.

Materials Used:

- Aluminum Oxide

- Silicon Carbide

- Ceramic Alumina

- Diamond

Market Analysis

Before importing grinding wheels, it’s crucial to understand the market demand and competition. Research the following:

- Key Markets: Identify the primary industries and regions that use grinding wheels.

- Trends: Stay updated on technological advancements and emerging trends in the manufacturing sector.

- Competitors: Analyze the market share and strategies of existing suppliers.

Selecting a Supplier

Finding a reliable supplier is critical. Here’s how to do it:

- Research: Use platforms like Alibaba, Global Sources, and industry-specific directories to find potential suppliers.

- Quality Certification: Ensure the supplier has relevant certifications like ISO 9001.

- Samples: Request samples to verify the quality of the grinding wheels.

- References and Reviews: Check reviews and ask for references from other buyers.

Understanding Import Regulations

Importing grinding wheels involves adhering to various regulations:

- Tariffs and Duties: Check the Harmonized Tariff Schedule (HTS) code for grinding wheels to determine applicable duties.

- Compliance: Ensure the products comply with safety standards such as OSHA or ANSI in the U.S., or equivalent standards in other countries.

- Documentation: Prepare necessary documents like commercial invoices, packing lists, and certificates of origin.

Shipping and Logistics

Efficient shipping and logistics are essential to minimize costs and ensure timely delivery:

- Freight Forwarders: Consider hiring a freight forwarder to handle shipping logistics.

- Incoterms: Understand International Commercial Terms (Incoterms) to clarify responsibilities between buyer and seller.

- Insurance: Insure your shipment to protect against potential loss or damage.

Cost Management

Managing costs effectively can make your import business more profitable:

- Bulk Purchasing: Buying in bulk can reduce the per-unit cost.

- Negotiation: Negotiate with suppliers for better pricing or favorable payment terms.

- Currency Exchange: Monitor exchange rates to minimize currency conversion costs.

Quality Control and Assurance

Maintaining the quality of grinding wheels is crucial:

- Inspections: Conduct pre-shipment inspections to ensure product quality.

- Testing: Implement rigorous testing procedures to confirm the grinding wheels meet the required specifications.

- Feedback Loop: Establish a feedback loop with your customers to continually improve product quality.

Marketing and Distribution

Once you’ve successfully imported grinding wheels, focus on marketing and distribution:

- Digital Marketing: Utilize SEO, PPC, and social media marketing to reach potential buyers.

- Trade Shows: Participate in industry trade shows to showcase your products.

- Distributor Network: Build a network of distributors to expand your market reach.

Conclusion

Importing grinding wheels can be a highly profitable business if approached with due diligence and strategic planning. By understanding the product, selecting reliable suppliers, navigating import regulations, and managing costs, you can establish a successful import operation. Stay informed about market trends and continuously improve your quality control processes to ensure long-term success in the industry.