In the world of metalworking, cutting, grinding, and other surface preparation processes, the choice of the right tool is paramount. Among the variety of abrasive tools available, ultra-thin cutting discs stand out due to their unique combination of precision, speed, and minimal heat generation. Whether you’re working with steel, stainless steel, or aluminum, ultra-thin cutting wheels offer several advantages that make them ideal for specific applications. In this blog, we’ll dive into the features, benefits, and best use cases for these cutting-edge tools.

What Are Ultra Thin Cutting Wheels?

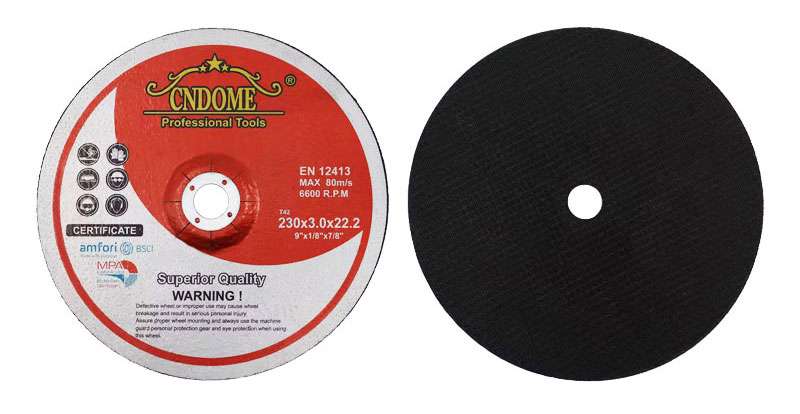

Ultra-thin cutting wheels are a specialized type of abrasive tool designed for cutting through various materials with minimal effort and maximum precision. Typically ranging from 0.8 mm to 1.5 mm in thickness, these wheels are much thinner than standard cutting wheels, offering several key benefits that make them indispensable in certain industries.

They’re engineered to operate at high speeds, allowing them to slice through materials like metal, stainless steel, and even composite materials without causing excessive heat buildup or material deformation. Due to their reduced thickness, these wheels require less power to cut, which can also result in longer tool life and reduced material wastage.

Key Benefits of Ultra Thin Cutting Wheels

- Precision Cutting The ultra-thin nature of these discs means they can deliver extremely clean and precise cuts, making them ideal for tasks where accuracy is crucial, such as in electronics, automotive, and aerospace industries.

- Minimal Heat Generation Thin cutting wheels generate significantly less heat during operation. This minimizes the risk of thermal damage to both the material being cut and the surrounding area, which is especially important when working with heat-sensitive materials like aluminum and stainless steel.

- Reduced Burr Formation Because the cutting process is more refined, ultra-thin wheels leave behind less burr or slag, resulting in smoother edges. This makes them perfect for applications where a clean finish is critical, reducing the need for secondary processes like deburring or grinding.

- Faster Cutting Speed The thin profile of the wheel means less resistance as it slices through materials, which translates to faster cutting speeds. Whether you’re working with thin sheet metal or intricate cuts, ultra-thin cutting wheels can get the job done quickly without compromising quality.

- Longer Tool Life Due to their efficient cutting action, ultra-thin discs tend to last longer than thicker wheels. This can be a major cost-saving factor in high-volume operations, where replacing tools frequently can add up.

Ideal Applications for Ultra Thin Cutting Wheels

Ultra-thin cutting discs excel in situations that demand precision and minimal heat buildup. Here are some common applications:

- Automotive Repair and Maintenance Ultra-thin cutting wheels are perfect for cutting car parts, such as exhaust systems, body panels, and suspension components. They can easily handle the delicate nature of automotive parts, making them a go-to for professionals in the industry.

- Aerospace and Aircraft Parts In the aerospace industry, where high tolerances and minimal heat distortion are critical, ultra-thin cutting wheels are used to cut and shape metal components with extreme precision.

- Electronics Manufacturing Cutting delicate electronics components, such as circuit boards and microelectronics, requires fine cuts without damaging the material or causing heat buildup. Ultra-thin cutting discs are a perfect solution for this.

- Metal Fabrication Whether cutting thin sheet metal, stainless steel, or even some alloys, these wheels provide smooth cuts that minimize material distortion, reducing the need for additional finishing steps.

Choosing the Right Ultra Thin Cutting Wheel

When selecting an ultra-thin cutting wheel, consider the following factors:

- Material Type: Different wheels are designed for different materials, so make sure the wheel you choose is suitable for the material you’re cutting (e.g., steel, aluminum, stainless steel).

- Cutting Speed: Some ultra-thin cutting wheels are designed to operate at higher speeds, so make sure your equipment can handle the wheel’s speed rating for optimal performance.

- Size and Thickness: While ultra-thin wheels are generally thinner than standard wheels, they still come in various sizes. Select the appropriate size for your specific cutting task.

- Bonding and Abrasive Material: The type of bonding material (resin, ceramic, etc.) and abrasive material (aluminum oxide, zirconia, etc.) used in the wheel can impact its durability and performance.

Conclusion

Ultra-thin cutting wheels are an invaluable tool for professionals seeking high-performance, precise, and efficient cutting solutions. Whether in automotive, aerospace, or metalworking industries, their ability to deliver clean cuts, minimize heat generation, and reduce burr formation make them the tool of choice for intricate tasks. With the right wheel in hand, operators can achieve exceptional results while minimizing tool wear and material waste.

The future of cutting technology is here, and ultra-thin cutting discs are leading the way to more efficient, precise, and cost-effective operations.

Online Message

Minimum Order Quantity: 5,000 Pcs, 10 Pcs Free Samples.

Contact Us For More Information!

Tel/WhatsApp

+86 18796960868

DomeGrinding@hotmail.com

Address