Cutting cast materials, such as cast iron or cast steel, requires precision, efficiency, and the right tools. Cutting discs specifically designed for cast materials are essential for achieving clean and precise cuts. In this blog, we’ll explore the key features, types, and benefits of cut-off wheels for cast materials, as well as tips for selecting and using them effectively.

Why Are Cut-Off Wheels for Cast Materials Unique?

Cut-off wheels for cast materials are engineered to handle the dense, brittle nature of cast iron and the toughness of cast steel. Their design takes into account the need for:

- High Durability: To withstand the hardness of cast materials without excessive wear.

- Sharp Cutting Edges: For clean cuts with minimal effort.

- Reduced Heat Generation: To prevent material cracking or distortion.

Key Features of Cut-Off Wheels for Cast Materials

- Material Composition:

- Aluminum Oxide: Commonly used for its toughness and adaptability to hard materials like cast iron.

- Silicon Carbide: Ideal for aggressive cutting of brittle materials, offering excellent sharpness.

- Bond Type:

- Resin-Bonded Wheels: Provide a balance between cutting speed and wheel durability.

- Metal-Bonded Wheels: Offer longer service life for heavy-duty applications.

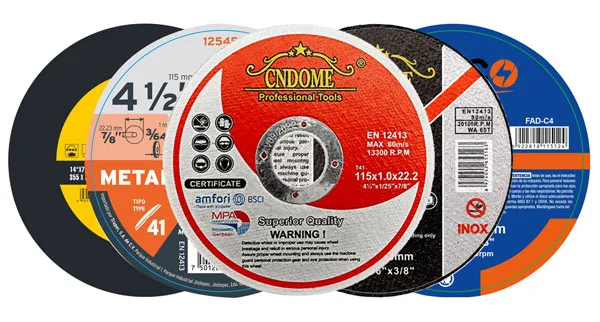

- Thickness and Diameter:

- Thin wheels (1–2 mm) are best for fast, precise cuts.

- Thicker wheels (2.5–3 mm) are more durable for heavy-duty cutting tasks.

Applications of Cut-Off Wheels for Cast Materials

Cutting discs for cast materials are versatile tools suitable for:

- Cutting Pipes and Tubes: Ideal for cast iron or cast steel pipelines.

- Metal Casting Trimming: Removing excess material from castings.

- Machinery Repairs: Cutting through heavy cast components for maintenance.

How to Select the Right Cut-Off Wheel for Cast Materials

- Identify the Material Type:

- For cast iron, choose a wheel with silicon carbide for aggressive performance.

- For cast steel, opt for aluminum oxide for durability and precision.

- Choose the Right Wheel Size:

- Match the wheel diameter with your cutting tool for optimal performance.

- Check the RPM Rating:

- Ensure the wheel’s maximum RPM rating matches your tool’s speed to prevent accidents.

- Evaluate the Cutting Environment:

- Use reinforced wheels for added safety in heavy-duty or high-pressure applications.

Tips for Using Cut-Off Wheels on Cast Materials

- Secure the Workpiece: Prevent vibrations or movement by clamping the material securely.

- Apply Consistent Pressure: Avoid excessive force to prevent wheel breakage and ensure smooth cuts.

- Control Heat Generation: Use proper cooling techniques, such as air or water, to maintain material integrity.

- Inspect the Wheel: Always check for cracks or wear before use to ensure safety.

Advantages of Using Specialized Cut-Off Wheels for Cast Materials

- Enhanced Productivity: Faster and more efficient cutting.

- Better Cut Quality: Reduced chipping or material cracking.

- Longer Wheel Life: Designed to withstand the demanding nature of cast materials.

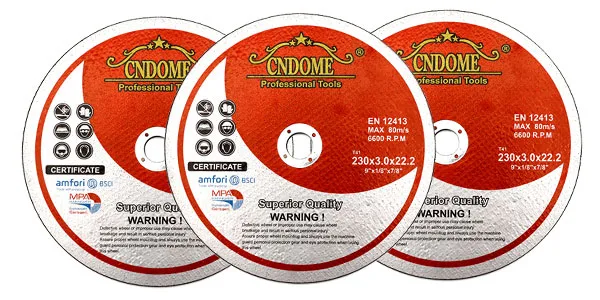

Popular Brands and Options

When selecting cut-off wheels, consider reputable brands known for quality and reliability. Some popular options include:

- Wheels with zirconia alumina for heavy-duty cast material cutting.

- Ultra-thin wheels for intricate or delicate cuts.

Conclusion

Cut-off wheels designed for cast materials are indispensable for achieving precision, safety, and efficiency in cutting tasks. By understanding the unique features and proper usage of these wheels, you can ensure optimal performance and durability in your projects. Whether you’re a professional or a DIY enthusiast, investing in the right tools for cast materials will elevate the quality and efficiency of your work.

Would you like to explore specific brands or types of cutting discs for cast materials? Let me know!