Rotary tools are incredibly versatile, capable of performing a wide range of tasks from sanding to polishing, engraving to drilling. One of the most common uses for a rotary tool is cutting, and for that, you’ll need a reliable cutting disc. In this guide, we’ll explore the different types of cutting discs available, their uses, and tips for getting the best performance from your rotary tools.

Types of Cutting Discs

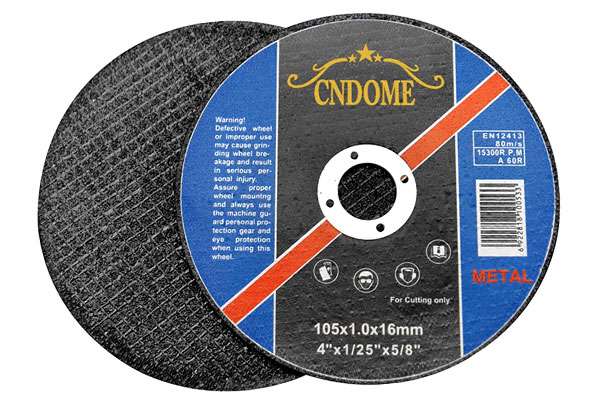

1. Metal Cutting Discs

- Material: Usually made from reinforced fiberglass or composite materials.

- Uses: Ideal for cutting through various metals such as steel, aluminum, and copper.

- Features: Durable and designed to handle the intense friction and heat generated when cutting metal.

2. Diamond Cutting Discs

- Material: Coated with diamond particles.

- Uses: Perfect for cutting through hard materials like stone, ceramics, and glass.

- Features: Long-lasting and capable of making clean, precise cuts even through the toughest materials.

3. Wood Cutting Discs

- Material: Often made from high-speed steel (HSS) or carbide.

- Uses: Specifically designed for cutting through various types of wood and wood composites.

- Features: Sharp teeth that can cut through wood smoothly without causing burns or excessive splintering.

4. Plastic Cutting Discs

- Material: Made from materials that minimize melting, such as reinforced fiberglass.

- Uses: Suitable for cutting through PVC, acrylic, and other types of plastic.

- Features: Designed to reduce the heat build-up that can cause plastic to melt during cutting.

Choosing the Right Cutting Disc

Selecting the appropriate cutting disc depends on the material you’re working with and the precision required for your project. Here are some factors to consider:

- Material Compatibility: Ensure the disc is rated for the material you intend to cut. Using the wrong type can result in poor performance or damage to the disc and material.

- Disc Size: Choose a disc that fits your rotary tool and is appropriate for the thickness of the material.

- Speed Rating: Check the maximum RPM rating of the disc and ensure it matches the speed of your rotary tool.

Tips for Using Cutting Discs

- Safety First: Always wear protective gear, including safety glasses, gloves, and a dust mask. Cutting discs can produce sparks, debris, and fine particles.

- Secure the Material: Ensure the material you’re cutting is firmly clamped or secured to prevent movement during cutting.

- Steady Hand: Hold the rotary tool with a steady hand and apply gentle, consistent pressure. Let the cutting disc do the work; forcing it can cause breakage.

- Cooling Periods: Take breaks if the disc or material becomes too hot. Overheating can damage both the disc and the material.

- Proper Storage: Store cutting discs in a dry place, away from moisture and extreme temperatures to maintain their integrity.

Maintenance and Replacement

Regular inspection and maintenance of your cutting discs can extend their lifespan and ensure optimal performance:

- Inspect for Damage: Before each use, check the disc for cracks, chips, or excessive wear. Replace damaged discs immediately.

- Clean the Disc: After use, clean the disc to remove any debris or residue that could affect future cuts.

- Proper Storage: Store your discs flat in a cool, dry place to prevent warping and deterioration.

Conclusion

Cutting discs are an essential accessory for any rotary tools, providing the ability to cut through a variety of materials with precision and ease. By understanding the different types of cutting discs and following best practices for their use and maintenance, you can ensure safe, efficient, and successful cutting projects. Whether you’re a DIY enthusiast or a professional, having the right cutting disc for your rotary tool will make all the difference in achieving high-quality results.