Mini cutting discs are small but powerful tools used in a variety of applications. Whether you’re a hobbyist, a DIY enthusiast, or a professional working in metalworking, construction, or automotive industries, these discs offer precision and control that larger cutting discs simply can’t match.

1. What are Mini Cutting Discs?

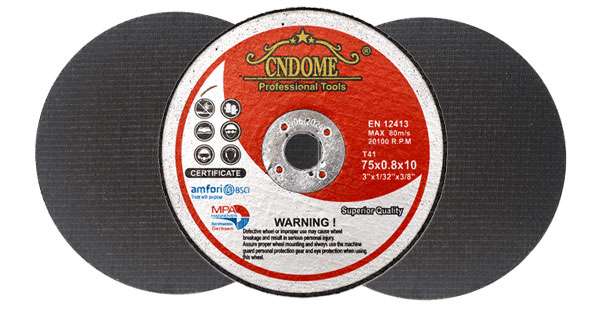

Mini cutting wheels are smaller versions of standard cutting wheels, typically ranging from 2 inches to 3 inches in diameter. Despite their size, they are made from the same high-quality abrasive materials, such as aluminum oxide, silicon carbide, or diamond, ensuring durability and efficiency.

2. Key Applications of Mini Cutting Discs

- Metalworking: Ideal for cutting small metal pieces, pipes, and sheet metal with precision.

- Jewelry Making: Perfect for delicate cuts in precious metals and gemstones.

- Automotive: Useful for cutting and trimming in tight spaces, such as under the hood or in the interior of vehicles.

- DIY Projects: Great for hobbyists working on detailed projects involving metal, plastic, or wood.

3. Types of Mini Cutting Wheels

- Flat Cutting Discs: Best for straight cuts on flat surfaces.

- Depressed Center Discs: Useful for working on curved or angled surfaces.

- Diamond Discs: Ideal for cutting hard materials like ceramics and stone.

4. What Materials Can Mini Cutting Discs Be Used For?

Mini cutting diss are versatile and can be used on a variety of materials, including:

- Metals (steel, aluminum, copper)

- Plastics (PVC, acrylic)

- Ceramics and tile

- Wood

5. Advantages of Using Mini Cutting Discs

- Precision: Their small size allows for precise cuts, especially in tight spaces.

- Control: Easier to handle than larger discs, making them ideal for detailed work.

- Versatility: Suitable for a wide range of materials and applications.

- Portability: Lightweight and easy to transport, making them a great addition to any toolbox.

6. Safety Tips for Using Mini Cutting Discs

- Always wear appropriate safety gear, including goggles, gloves, and a face shield.

- Ensure the disc is securely attached to the tool before use.

- Use the correct speed settings to avoid disc breakage.

- Do not force the disc; let it cut at its own pace to prevent overheating.

7. Choosing the Right Mini Cutting Disc for Your Project

When selecting a mini cutting disc, consider the material you’ll be cutting, the type of tool you’re using, and the specific needs of your project. For example, if you’re cutting hard materials like tile or stone, a diamond disc would be the best choice.

Conclusion

Mini cutting discs are indispensable tools for anyone who requires precision and versatility in their cutting tasks. By understanding their applications, types, and safety considerations, you can make the most out of these small but mighty discs in your next project.