Flap discs are versatile and efficient tools used in various applications, from metalworking to woodworking. When it comes to paint removal, they offer several advantages over traditional methods. This blog will delve into why flap discs are a go-to choice for paint removal, how to choose the right one, and tips for effective use.

Why Choose Flap Discs for Paint Removal?

- Efficiency: Flap discs combine the functions of grinding wheels and sanding discs, allowing for rapid paint removal while smoothing the surface simultaneously.

- Durability: Made from high-quality materials, flap discs last longer than traditional sandpaper, reducing the frequency of replacements.

- Versatility: Available in various grit sizes, flap discs can handle different levels of paint removal, from heavy-duty stripping to fine sanding.

- Ease of Use: They are designed to be user-friendly, providing a consistent finish with minimal effort.

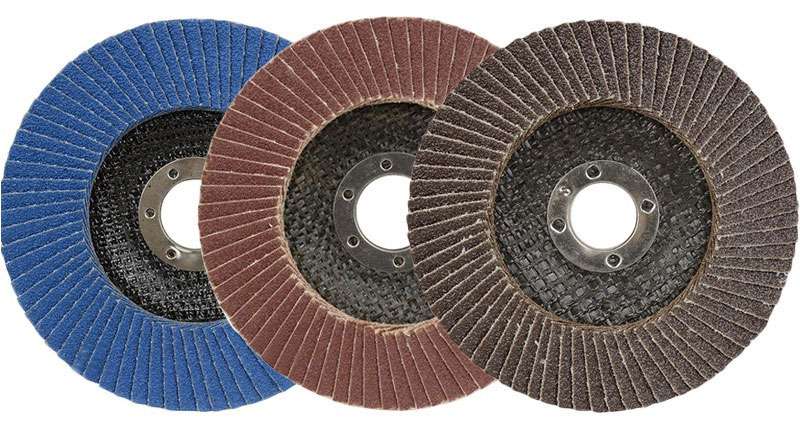

Types of Flap Discs

Understanding the different types of flap discs is crucial for selecting the right one for your paint removal project. Here are some common types:

- Aluminum Oxide Flap Discs: Ideal for general-purpose use, they are suitable for removing paint from metal and wood surfaces.

- Zirconia Alumina Flap Discs: Known for their durability and high-performance, these discs are perfect for tougher jobs, including removing thick paint layers and rust.

- Ceramic Flap Discs: These discs are designed for heavy-duty applications and offer excellent performance on hard surfaces. They are more expensive but last longer and cut faster.

Choosing the Right Grit Size

Grit size is another critical factor in selecting the appropriate flap disc for paint removal. The grit size determines the coarseness of the disc:

- Coarse Grit (40-60): Suitable for heavy paint removal and initial sanding of rough surfaces.

- Medium Grit (80-120): Ideal for removing medium layers of paint and smoothing surfaces.

- Fine Grit (150-240): Best for final sanding and preparing the surface for painting or finishing.

How to Use Flap Discs for Paint Removal

- Safety First: Always wear protective gear, including gloves, goggles, and a dust mask, to protect yourself from debris and dust.

- Prepare the Surface: Clean the surface to remove any loose debris or dirt. This will ensure the flap disc works more effectively.

- Angle and Pressure: Hold the angle grinder at a 15-30 degree angle to the surface. Apply even pressure and move the grinder in a steady, sweeping motion.

- Check Progress: Periodically stop to check your progress and adjust your technique as needed. This helps prevent over-grinding and ensures an even finish.

- Finishing Touches: Once the paint is removed, you may need to switch to a higher grit disc for final smoothing and preparation for repainting or other treatments.

Tips for Best Results

- Use the Right Speed: Running your angle grinder at the appropriate speed for the disc and material will enhance performance and disc life.

- Avoid Overheating: Overheating can damage both the flap disc and the workpiece. Take breaks if necessary to let the surface cool.

- Replace Worn Discs: Using a worn-out disc can reduce efficiency and cause uneven grinding. Replace discs when they show signs of significant wear.

Conclusion

Flap discs are a valuable tool for anyone involved in paint removal projects. Their efficiency, versatility, and ability to provide a superior surface finish make them an excellent choice over traditional sanding methods. By selecting the right flap disc and using proper techniques, you can achieve professional results with less effort and time.

Whether you’re refurbishing furniture, restoring vehicles, or preparing surfaces for a fresh coat of paint, flap discs can help you get the job done efficiently and effectively. Invest in high-quality flap discs and experience the difference they can make in your paint removal projects.