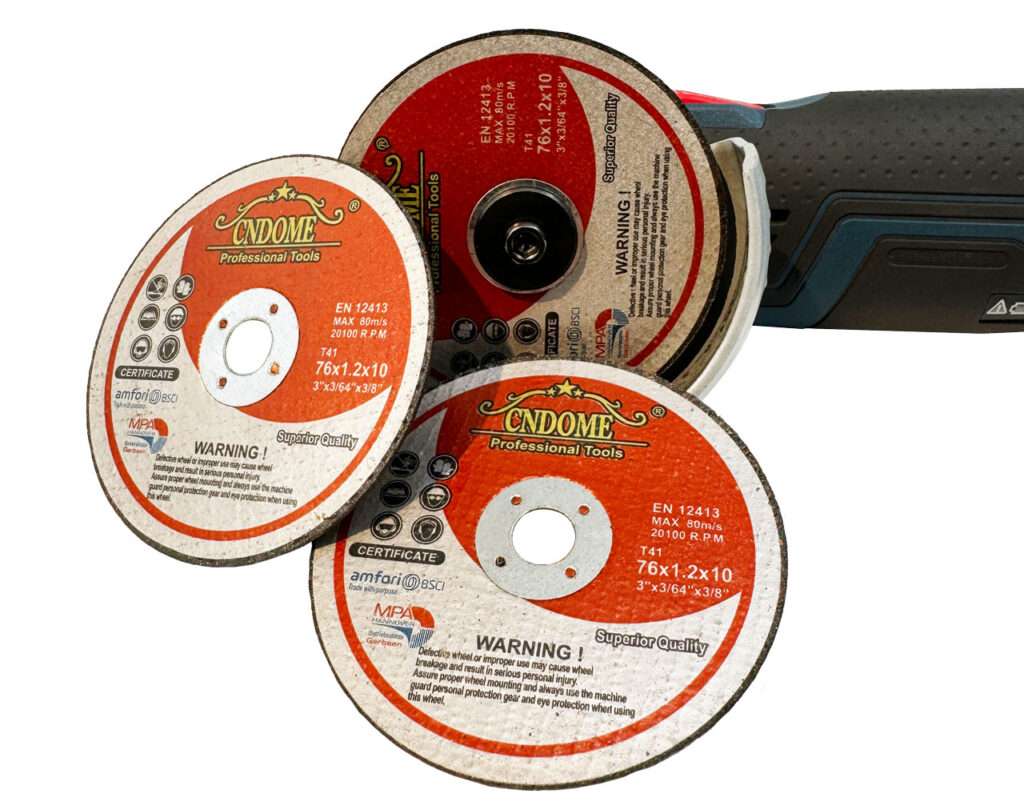

When it comes to precision cutting in tight spaces, 3-inch cut-off wheel is an essential tool for both professionals and DIY enthusiasts. Compact yet powerful, these wheels can handle a variety of materials, making them a versatile choice for many applications. In this blog, we’ll explore the key features, benefits, and best practices for using 3-inch cut-off wheel.

What Are 3-Inch Cut-Off Wheels?

3-inch cut-off wheels are thin, circular discs designed for cutting through metal, plastic, wood, and other materials. They are commonly used with angle grinders and small bench saws, allowing for precise cuts in confined spaces. These wheels are particularly favored for their portability and efficiency, making them ideal for tasks that require maneuverability.

Key Features

- Material Composition: Most 3-inch cut-off wheels are made from abrasive materials like aluminum oxide, silicon carbide, or diamond. The choice of material affects the wheel’s durability and cutting ability.

- Thickness: The thickness of the wheel influences the speed and precision of the cut. Thinner wheels (usually around 1/16 inch) cut faster and require less force, but they may wear out more quickly compared to thicker options.

- Arbor Size: 3-inch cut-off wheels typically have a standard arbor size of 1/4 inch, making them compatible with most small grinders.

Benefits of Using 3-Inch Cut-Off Wheels

- Precision Cutting: The smaller diameter allows for more control and precision, making them suitable for intricate tasks and tight spaces.

- Versatility: These wheels can cut through a variety of materials, including metal, plastics, ceramics, and even some composites. This versatility makes them a valuable addition to any toolkit.

- Easy to Handle: Their lightweight design means they can be used for extended periods without causing fatigue, making them perfect for detailed work.

- Cost-Effective: Smaller wheels often come at a lower price point, allowing users to stock up without breaking the bank.

Applications

3-inch cut-off wheels are used in various industries and applications, including:

- Metalworking: Ideal for cutting small metal pieces or finishing edges.

- Plumbing: Perfect for cutting pipes and fittings in tight spaces.

- Automotive Repairs: Great for slicing through rusted or damaged components.

- Craft Projects: Useful for intricate cuts in wood or plastic for DIY projects.

Best Practices for Using 3-Inch Cut-Off Wheels

- Safety First: Always wear appropriate safety gear, including goggles, gloves, and a dust mask, to protect against flying debris.

- Proper Equipment: Ensure your angle grinder or saw is compatible with 3-inch cut-off wheels and is in good working condition.

- Cutting Technique: Use a steady, consistent pressure when cutting. Let the wheel do the work—forcing it can lead to premature wear or breakage.

- Check for Damage: Before use, inspect the wheel for any cracks or defects. A damaged wheel can shatter during use, posing a significant safety risk.

- Maintain Your Tools: Regularly clean and maintain your grinder or saw to ensure optimal performance and longevity of both the tool and the wheels.

Conclusion

3-inch cut-off wheels are a compact and versatile tool that can enhance your cutting capabilities across a wide range of materials. Whether you’re a professional tradesperson or a weekend warrior, these wheels are an excellent addition to your toolkit. By following best practices and safety guidelines, you can maximize their efficiency and effectiveness for all your cutting needs.

Invest in quality 3-inch cut-off wheels, and enjoy the precision and convenience they bring to your projects!