Abrasive cut-off discs are essential tools in industries ranging from construction to automotive and metalworking. These versatile tools are designed to cut through materials like metal, stone, ceramics, and plastics, making them a go-to choice for professionals who need precision and reliability. But what exactly makes an abrasive cut-off disc tick? In this blog, we’ll explore their features, types, and how to use them effectively for the best results.

What is an Abrasive Cut-Off Disc?

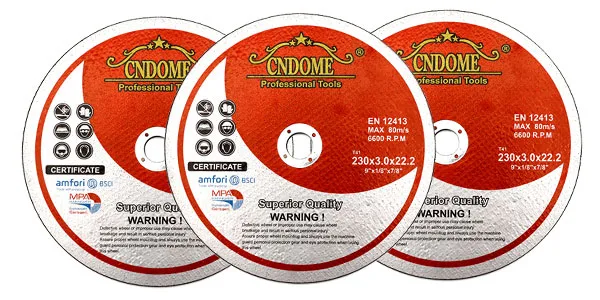

An abrasive cut-off disc is a thin, circular tool made from abrasive particles (like aluminum oxide or silicon carbide) bound together with a resin or other bonding agents. It’s typically mounted on a grinder or power tool and used to cut through various materials by applying high-speed friction. The abrasive nature of the disc helps it slice through hard materials, effectively wearing away the surface as it moves.

Key Features of Abrasive Cut-Off Discs

- Material Composition:

Different abrasive materials are used for different tasks. For example, aluminum oxide is commonly used for cutting steel and other ferrous metals, while silicon carbide is more suited for cutting non-ferrous metals, concrete, and stone. - Thickness:

The thickness of the disc impacts cutting speed and precision. Thicker discs tend to be more durable but may cut slower, while thinner discs offer faster cuts but might wear out more quickly. - Size:

Abrasive cut-off discs come in various sizes, with common diameters being 4 ½”, 5”, and 9”. The size of the disc should match the job’s requirements, as well as the tool it’s mounted on. - Grain Size:

The grain size of the abrasive material determines how aggressive the disc is. A coarser grain offers faster cuts but can lead to a rougher finish, while a finer grain is slower but delivers a smoother cut. - Bonding:

The bonding material holds the abrasive grains in place. A stronger bond improves the disc’s durability, but it can also reduce the rate at which the disc wears down. Common bonding agents include resins, rubber, and metal.

Types of Abrasive Cut-Off Discs

- Metal Cut-Off Discs:

These are designed to cut through steel, stainless steel, and other metal alloys. They come in various grit levels, with finer grit discs delivering smoother cuts. These discs are often used in fabrication, automotive repair, and construction. - Stone/Concrete Cut-Off Discs:

If you’re working with masonry, concrete, or stone, you’ll need a disc specifically designed to handle the abrasiveness of these materials. These discs typically have a diamond or silicon carbide abrasive for better cutting performance. - Inox/Metal-Specific Cut-Off Discs:

For cutting stainless steel (Inox), look for cut-off discs specifically formulated for this material. These discs reduce the risk of overheating and contamination, which can affect the quality of the cut.

How to Choose the Right Abrasive Cut-Off Disc

Choosing the right disc is crucial for achieving the best results. Here are some factors to consider:

- Material Being Cut:

Different materials require different discs. Always choose a disc that’s suitable for the material you’re working with (metal, stone, etc.). - Tool Compatibility:

Ensure that the cut-off disc matches the size and type of grinder or cutting tool you are using. Mismatched tools can cause accidents and suboptimal results. - Cutting Speed and Precision:

Depending on whether you need a fast, rough cut or a precise, smooth cut, the thickness and grain size of the disc should vary. Thin, fine-grit discs provide cleaner, more precise cuts, while thick discs are better for faster cutting through tough materials. - Safety Considerations:

Always prioritize safety when using abrasive cut-off discs. These tools can generate a lot of sparks and heat. Be sure to wear protective gear, including goggles, gloves, and face shields, and follow proper usage instructions.

How to Use Abrasive Cut-Off Discs Safely

- Wear Protective Gear:

Always wear the right PPE—goggles, gloves, ear protection, and a dust mask. Abrasive cutting generates a lot of sparks, dust, and noise. - Secure the Workpiece:

Always clamp or secure the material you’re cutting to prevent it from shifting during the cut. - Check the Disc for Damage:

Inspect the cut-off disc for any cracks or defects before use. A damaged disc can break or shatter during use, posing serious safety risks. - Maintain Consistent Pressure:

Apply even, consistent pressure when cutting. Don’t force the disc; let the tool do the work. Too much pressure can cause the disc to wear out faster and may result in an uneven cut. - Keep the Work Area Clean:

Ensure your workspace is free from flammable materials, as sparks are a common byproduct of abrasive cutting.

Conclusion

Abrasive cut-off discs are invaluable tools for cutting through tough materials. By understanding the different types and features of these discs, as well as how to use them safely, you can enhance both the quality of your work and your safety. Whether you’re working on a DIY project or in a professional setting, choosing the right abrasive cut-off disc is key to achieving precise, efficient results.