Cutting discs are essential tools in various industries, from metalworking to construction. They’re used to cut through a range of materials including metal, masonry, and concrete. However, to get the most out of your cutting discs, it’s important to understand their service life and how to maximize it. Here’s a comprehensive guide to help you.

What Affects the Service Life of Cutting Discs?

- Material Being Cut: The type of material you’re cutting significantly impacts the lifespan of your disc. Harder materials like stainless steel can cause more wear on the disc compared to softer metals like aluminum.

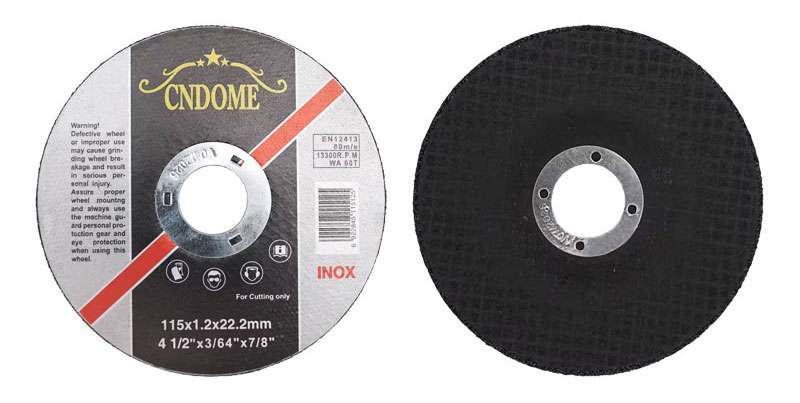

- Disc Quality: Higher-quality discs generally have a longer service life. Investing in reputable brands can ensure better performance and durability.

- Cutting Speed and Pressure: Excessive speed or pressure can lead to faster wear and tear. Always use the recommended speed for your disc and apply even pressure.

- Proper Storage and Handling: Store cutting discs in a dry, cool place. Avoid exposing them to extreme temperatures or moisture, which can affect their performance. Handle them carefully to prevent damage.

- Equipment Maintenance: Ensure your cutting equipment is in good condition. Misalignment or malfunctioning machinery can lead to uneven wear on the discs.

How to Extend the Service Life of Your Cutting Discs

- Use the Right Disc for the Job: Different discs are designed for different materials and tasks. Make sure you’re using a disc suited to the material and the type of cut required.

- Follow Manufacturer Guidelines: Adhere to the manufacturer’s recommendations for speed, pressure, and usage. This helps avoid unnecessary wear and prolongs the disc’s life.

- Regular Maintenance: Keep your equipment clean and well-maintained. Regularly check for any signs of wear or damage and replace parts as needed.

- Proper Technique: Use smooth and steady movements when cutting. Avoid forcing the disc through the material, as this can cause excessive wear.

- Check for Wear: Regularly inspect your discs for signs of wear or damage. Replace discs that are worn out or have visible defects.

Conclusion

Understanding and managing the service life of your cutting discs is crucial for maintaining efficiency and safety in your work. By considering factors like material type, disc quality, and proper maintenance, you can extend the lifespan of your cutting discs and ensure optimal performance. Regular inspection and adherence to best practices will keep your cutting operations running smoothly.

Online Message

Minimum Order Quantity: 5,000 Pcs, 10 Pcs Free Samples.

Contact Us For More Information!

Tel/WhatsApp

+86 18796960868

DomeGrinding@hotmail.com

Address