In the realm of metalworking, precision is paramount. From crafting intricate designs to shaping robust structures, every cut counts. This is where the cut-off wheel for die grinders emerges as a quintessential tool, blending finesse with force to sculpt metal with unparalleled accuracy. In this blog, we delve into the intricacies of this indispensable tool, exploring its features, applications, and the artistry it empowers.

Unveiling the Cut-Off Wheel

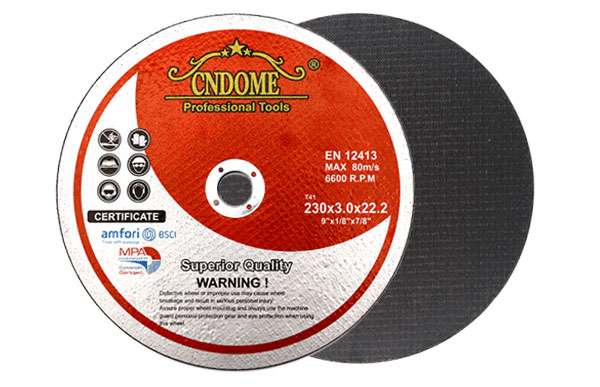

The cut-off wheel for die grinders is a marvel of engineering, designed to slice through metal with surgical precision. Unlike traditional abrasive discs, these wheels are compact, enabling them to access tight spaces and execute detailed cuts effortlessly. Crafted from robust materials such as aluminum oxide or silicon carbide, they boast exceptional durability, ensuring longevity even under intense workloads.

Precision in Action

Whether in automotive repair, metal fabrication, or DIY projects, the cut-off wheel proves its mettle across diverse domains. Its ability to carve through various metals, including steel, aluminum, and stainless steel, makes it a versatile ally in the workshop. From trimming bolts to shaping intricate components, its razor-sharp edge and controlled maneuverability make light work of intricate tasks.

Safety First

While the cut-off wheel empowers users with unparalleled precision, safety remains paramount. Protective gear, including goggles and gloves, shield against debris and potential hazards. Additionally, securing workpieces firmly in place prevents slippage, ensuring precise cuts while minimizing the risk of accidents.

Mastery Through Technique

Operating a cut-off wheel demands finesse and technique. Maintaining a steady hand and applying controlled pressure ensures smooth, accurate cuts. Rotating the workpiece as needed allows for uniform shaping, while judicious adjustments to speed and angle optimize performance. Mastery of these techniques transforms the cut-off wheel into a precision instrument, elevating craftsmanship to new heights.

Choosing the Right Wheel

Selecting the ideal cut-off wheel hinges on various factors, including material type, thickness, and application. While thinner wheels excel in intricate cuts, thicker variants offer enhanced durability for heavier tasks. Understanding these nuances empowers artisans to select the perfect tool for each project, maximizing efficiency and results.

Conclusion: Crafting Excellence

In the realm of metalworking, precision reigns supreme. The cut-off wheel for die grinders stands as a testament to this ethos, blending precision with power to shape metal with unparalleled accuracy. From automotive repairs to intricate craftsmanship, its versatility and finesse empower artisans to unleash their creativity and bring their visions to life. With safety as a steadfast companion and technique as their guiding light, craftsmen wield this tool as a brush, painting strokes of excellence upon the canvas of metal.