Metal cutting discs are indispensable tools for various applications, from construction to metalworking. They come in various shapes and sizes, each serving a specific purpose. One crucial aspect to consider when selecting a metal cutting disc is its thickness. In this blog, we’ll explore the importance of metal cutting disc thickness and guide you on how to choose the right dimension for your projects.

The Basics: Understanding Metal Cutting Discs

Before delving into thickness, let’s briefly understand the fundamentals of metal cutting discs. These discs are composed of abrasive materials bonded together with a resin. When attached to a compatible power tool, such as an angle grinder, they are used to cut, grind, or polish various types of metal and other materials.

Why Thickness Matters

The thickness of a metal cutting disc is a critical factor that impacts its performance and safety. It affects various aspects of the cutting process, including:

Cutting Speed: Thicker discs generally cut more slowly than thinner ones. A thicker disc has more material to remove, resulting in a slower cut. This can be advantageous for precision cutting, but it may not be the best choice when speed is essential.

Durability: Thicker discs tend to last longer because they have more material to wear down. If you’re working on a project that requires extensive cutting, a thicker disc can be a better investment.

Stability: A thicker disc is often more stable during cutting, which can be crucial for tasks that require a steady hand and precise control. Thicker discs are less likely to flex or wobble, leading to a smoother cut.

Heat Management: Thicker discs can dissipate heat more effectively, reducing the risk of overheating and potential discoloration or deformation of the metal being cut.

Choosing the Right Thickness

The right metal cutting disc thickness depends on the specific requirements of your project. Here’s a rough guideline:

Thin Discs (1-2mm): Thin discs are ideal for quick, straight cuts in thin materials. They’re great for making precision cuts but may wear down more quickly.

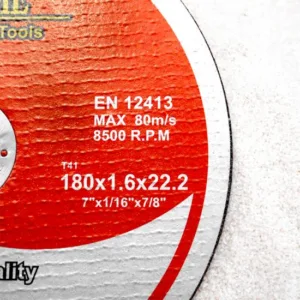

Medium Discs (2-3mm): These are versatile and can handle a wide range of applications. They offer a balance between cutting speed and durability.

Thick Discs (3mm and above): Thick discs are suitable for heavy-duty cutting tasks and projects that require a steady hand and extended usage. They’re robust and long-lasting.

Safety First

Remember, regardless of thickness, always prioritize safety when using metal cutting discs. Wear appropriate personal protective equipment, follow the manufacturer’s recommendations, and ensure that the tool and disc are compatible. Safety should be the top consideration in any cutting task.

In conclusion, the thickness of a metal cutting disc is a crucial factor that influences cutting speed, durability, stability, and heat management. To choose the right thickness, consider the demands of your specific project. Whether it’s precision work with a thin disc or heavy-duty cutting with a thicker one, selecting the appropriate thickness will help you achieve the best results safely and efficiently.