In the intricate world of manufacturing and craftsmanship, precision is paramount. Whether it’s cutting through tough metals or delicate materials with finesse, having the right tools can make all the difference. Among these tools, resin-bonded precision cutting discs stand out as indispensable companions for achieving accurate cuts and fine finishes. Let’s delve into the realm of resin bonded cutting discs, unraveling their significance, applications, and the nuances of their classification.

The Essence of Resin-Bonded Cutting Discs

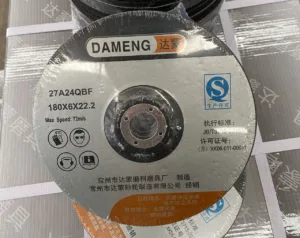

Resin-bonded cutting disks are high-performance tools crafted for precision cutting across a wide range of materials. They are composed of abrasive grains bonded together by a resin matrix, forming a sturdy, circular disc. This resin bond not only holds the abrasive grains in place but also provides stability and durability during cutting operations.

Applications Across Industries

Resin-bonded cutting discs find applications across various industries, from metalworking and construction to automotive and aerospace. These versatile discs are capable of cutting through metals, alloys, ceramics, plastics, and even stone with remarkable precision and efficiency.

In metalworking, resin-bonded cutting disks are indispensable for tasks such as cutting sheet metal, pipes, rods, and profiles. They offer clean cuts with minimal burrs, enhancing the quality and efficiency of manufacturing processes. Similarly, in construction and renovation projects, these cutting discs are used for precise cutting of tiles, bricks, and concrete, ensuring accuracy and speed on the job site.

Key Considerations for Classification

When classifying resin-bonded cutting discs under the HS code, several factors come into play. These include the diameter and thickness of the disc, the type and size of abrasive grains used, the hardness and density of the resin bond, and any additional features such as reinforced layers or cooling holes.

Moreover, the intended use of the cutting disc influences its classification. Discs designed for heavy-duty industrial applications may have different HS codes compared to those intended for DIY or hobbyist use.

Trade Implications and Compliance

Accurate classification of resin-bonded cutting disks under the HS code is essential for international trade. Importers and exporters must ensure compliance with customs regulations and tariffs to facilitate smooth transactions across borders.

Furthermore, understanding the HS code facilitates market analysis, product tracking, and regulatory compliance, ultimately fostering transparency and trust in global trade relationships.

Conclusion

Resin-bonded cutting disks epitomize precision and versatility in the realm of manufacturing and craftsmanship. From shaping metal components to cutting intricate patterns in delicate materials, these cutting discs are indispensable tools for achieving impeccable results.

Understanding the HS code for resin-bonded cutting discs is crucial for navigating the complexities of international trade. By accurately classifying these products, businesses can ensure compliance with customs regulations, streamline cross-border transactions, and foster a seamless global marketplace for these essential tools of precision cutting.