Rotary tools are a DIY enthusiast’s best friend, offering precision and versatility for a wide range of projects. One of the key accessories that enhances a rotary tool’s cutting capabilities is the cutting disc. These small, but mighty, discs open up a world of possibilities for craftsmen, hobbyists, and professionals alike. In this blog post, we’ll explore the various aspects of cutting discs for rotary tools, from types and materials to safety tips and project ideas.

Types of Cutting Discs:

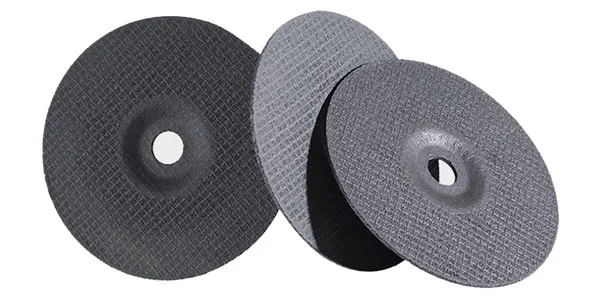

1. Fiber Reinforced Cutting Discs:

Composed of abrasive materials embedded in a fiberglass mesh, these discs are durable and suitable for cutting various materials, including metal and plastic. The reinforced structure adds strength and longevity to the disc.

2. Diamond Cutting Discs:

Ideal for cutting hard materials like ceramics, glass, and stone, diamond cutting discs feature a coating of industrial diamonds on the cutting surface. This makes them extremely effective for precise and clean cuts.

3. Abrasive Metal Cutting Discs:

Designed specifically for cutting through metal, these discs are often thinner and may wear out faster than other types. They are available in various grits to suit different metal cutting applications.

4. Wood Cutting Discs:

These discs have a design optimized for cutting through wood efficiently. They often feature carbide teeth or other tooth-like structures for smoother and faster cuts in wood and wood-related materials.

Choosing the Right Cutting Disc:

Selecting the appropriate cutting disc depends on the material you are working with. Ensure that the disc’s specifications match the requirements of your project, considering factors such as disc diameter, thickness, and the type of material you intend to cut. Using the wrong disc can result in inefficient cutting, damage to the material, or even pose safety risks.

Safety Tips:

1. Protective Gear:

Always wear appropriate personal protective equipment (PPE), including safety glasses or goggles, gloves, and a dust mask, to shield yourself from potential hazards like sparks and debris.

2. Secure Workpiece:

Secure the workpiece firmly in place using clamps or other suitable methods. This ensures stability during the cutting process, preventing accidents and achieving more accurate cuts.

3. Check Rotary Tool Compatibility:

Ensure that the cutting disc is compatible with your rotary tool. Different tools may have specific requirements for disc sizes and mounting mechanisms.

4. Follow Manufacturer Guidelines:

Adhere to the manufacturer’s guidelines for both the rotary tool and cutting disc. This includes proper installation, operating speed, and maintenance procedures.

Project Ideas:

1. Metal Sculptures:

Craft intricate metal sculptures by using cutting discs to shape and refine metal pieces with precision.

2. Custom Woodworking:

Create custom wooden pieces or intricate designs by using wood cutting discs to make precise cuts in various types of wood.

3. Tile Mosaics:

Use diamond cutting discs to cut and shape tiles for unique mosaic projects, adding a personalized touch to your home decor.

4. Jewelry Making:

Craft detailed jewelry pieces by using cutting discs to shape and refine metal components with precision.

Conclusion:

Cutting discs for rotary tools are indispensable accessories that empower DIY enthusiasts and professionals to tackle a diverse range of projects. By understanding the types of cutting discs available, choosing the right one for your needs, and following safety guidelines, you can unlock the full potential of your rotary tool and bring your creative ideas to life. So, gear up, secure your workspace, and let the cutting discs transform your projects into works of art.