When it comes to demanding grinding and finishing applications, Zirconia flap disc is among the top choices for professionals who need durability, efficiency, and versatility. Whether you’re working with metal, stainless steel, or other hard materials, these discs offer a combination of performance and longevity that makes them ideal for heavy-duty tasks. In this blog, we’ll take a closer look at what makes Zirconia flap discs stand out and how they can enhance your grinding projects.

What Are Zirconia Flap Disc?

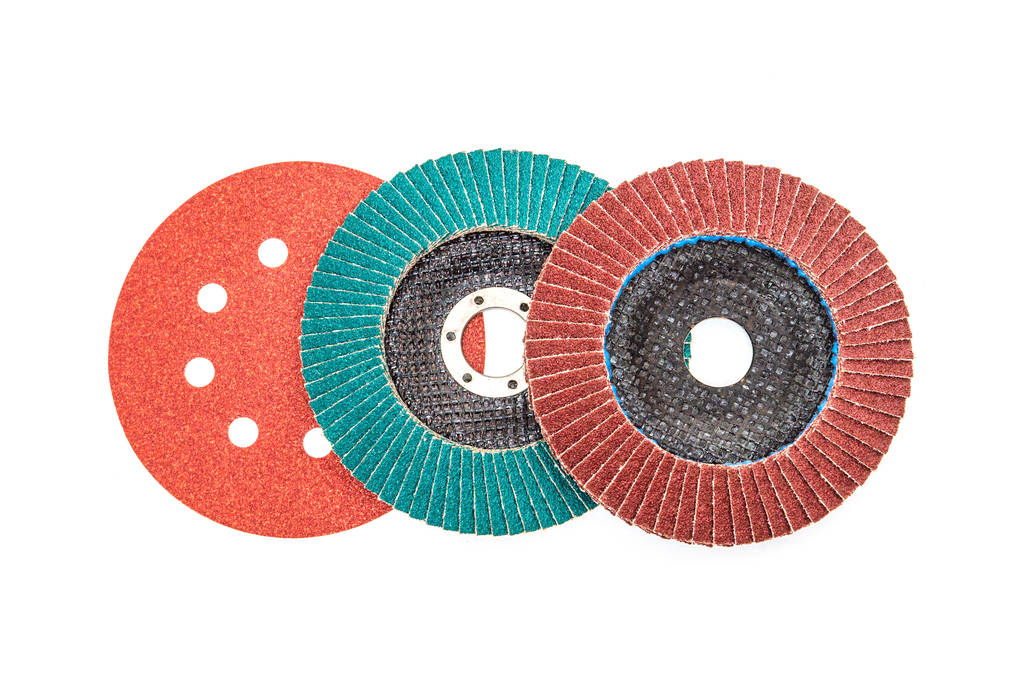

Zirconia flap discs are a type of abrasive disc composed of a specialized material called zirconia alumina, which is known for its toughness and resistance to heat. The flaps, or individual layers of abrasive material, are attached to a central backing plate. This design allows the flap disc to deliver a consistent cut while wearing down evenly over time. As the surface of the disc wears, fresh abrasive material is exposed, which helps maintain high grinding efficiency.

These discs are particularly effective for applications that require aggressive stock removal and smooth finishes. Zirconia alumina is harder than many other abrasives, which allows it to cut through tougher materials with ease.

Why Choose Zirconia Flap Discs?

- High Stock Removal Rate Zirconia flap discs are ideal for aggressive material removal. Thanks to the hardness and sharpness of zirconia alumina, these discs can tackle even the most stubborn surfaces with minimal effort. This makes them perfect for heavy grinding tasks like weld removal, rust and paint stripping, and deburring.

- Longer Service Life The unique properties of zirconia make it highly resistant to wear. Flap discs made with this material tend to last longer than those made with standard aluminum oxide or silicon carbide, especially in high-pressure, high-heat environments. This longevity translates to reduced downtime and fewer disc replacements, which is crucial for both cost-efficiency and productivity in industrial settings.

- Consistent Finish As zirconia alumina flap discs wear down, they continuously expose fresh, sharp abrasive material. This means they maintain a consistent cutting and finishing performance throughout the life of the disc. This is particularly valuable for applications that require both material removal and fine finishing, such as polishing stainless steel or preparing a surface for coating.

- Heat Resistance Zirconia flap discs have excellent heat resistance, making them suitable for applications that generate a lot of friction and heat. They won’t degrade as quickly as some other abrasives under intense heat, which helps maintain their effectiveness in high-speed grinding.

- Versatile Applications Zirconia flap discs can be used for a wide range of applications, including:

- Metalworking: Grinding and finishing steel, stainless steel, and other metals

- Weld Cleaning: Removing weld spatter and smoothing welds

- Paint and Rust Removal: Stripping coatings from metal surfaces

- Deburring: Removing sharp edges or burrs from machined parts

- Finishing: Polishing and achieving a smooth, uniform finish on various surfaces

Types of Zirconia Flap Discs

Zirconia flap discs come in different configurations, each designed for specific applications. The two primary types are:

- Type 29 (Conical Flap Discs): Type 29 flap discs are angled at approximately 15-25 degrees, which makes them more aggressive. These discs are perfect for heavy grinding and material removal, especially on flat surfaces or areas that require a deeper cut.

- Type 27 (Flat Flap Discs): Type 27 flap discs are flat, offering a more controlled and smooth finish. They are ideal for tasks where precision and a finer finish are important, such as surface preparation or finishing on delicate materials.

Choosing the Right Zirconia Flap Disc

To get the best performance from your Zirconia flap discs, consider the following factors:

- Grit Size:

- Coarse grits (36, 40, 60) are best for heavy stock removal.

- Medium grits (80, 120) are suitable for general grinding and finishing.

- Fine grits (150, 180, 220) are ideal for smoothing surfaces and achieving a polished finish.

- Material Being Worked On: Zirconia flap discs work best on metals such as steel, stainless steel, and cast iron. For non-ferrous materials, choose a disc with the appropriate grit size to avoid clogging and ensure optimal performance.

- Speed and Pressure: Zirconia flap discs are designed to work well at high speeds, but applying excessive pressure can cause premature wear or damage. It’s important to balance speed and pressure to maximize the lifespan and effectiveness of the disc.

Conclusion

Zirconia flap discs are a must-have tool for any professional or DIY enthusiast who needs high-performance, long-lasting abrasive discs. With their aggressive cutting action, resistance to heat, and ability to provide consistent finishes, they are ideal for a variety of applications, from metalworking to weld cleaning. Whether you’re performing heavy stock removal or polishing delicate surfaces, Zirconia flap discs offer a combination of durability and precision that makes them an invaluable asset in your toolkit.

Investing in high-quality Zirconia flap discs can save you time, reduce costs, and help you achieve the perfect finish every time.

Do you need any recommendations on specific brands or tips for optimizing your use of flap discs?

Online Message

Minimum Order Quantity: 5,000 Pcs, 10 Pcs Free Samples.

Contact Us For More Information!

Tel/WhatsApp

+86 18796960868

[email protected]

Address