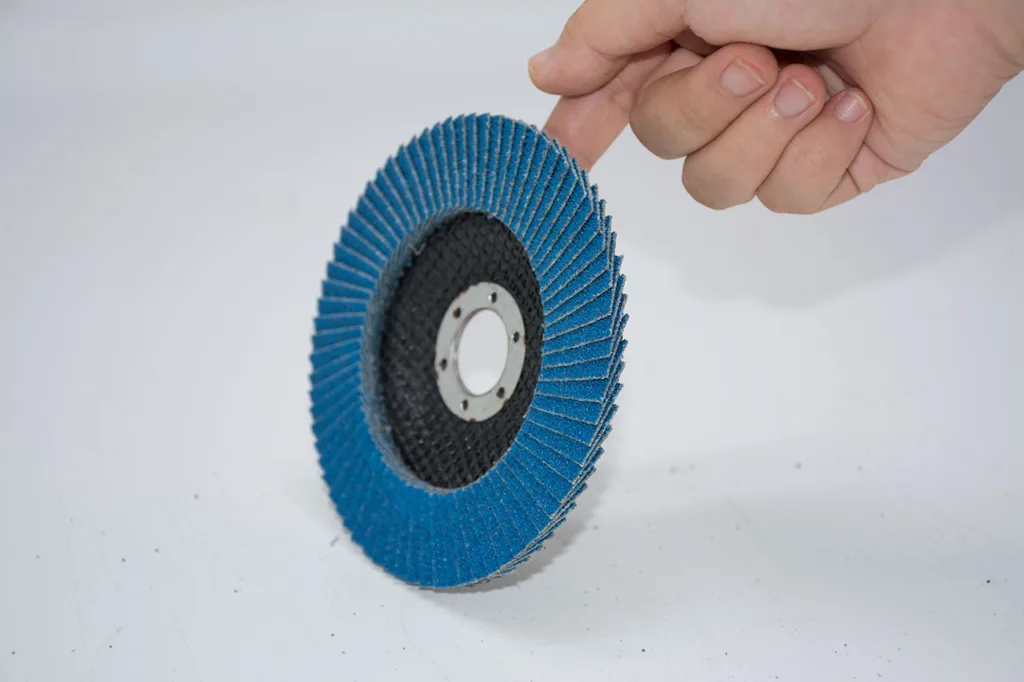

In the world of abrasives, understanding the nuances of various tools and accessories is key to achieving optimal results in your grinding and finishing tasks. Flap discs are widely used for their versatility, but what’s the deal with 27 flap discs and 29 flap discs? Let’s dive into the differences and help you choose the right one for your application.

Size Matters

The primary distinction between 27 and 29 flap discs lies in their size. These numbers refer to the outer diameter of the disc. A 27 flap disc has a diameter of 4.5 inches, while a 29 flap disc measures 7 inches. This size variance directly impacts their performance and applications.

Grinding Surface

One of the most noticeable differences is the size of the grinding surface. A 29 flap disc, being larger, covers a greater area during grinding. This larger surface can be advantageous for jobs that require a wider grind, such as smoothing large surfaces, blending welds over a broad area, or quickly removing material from larger workpieces.

Speed and Material Removal

The size of the flap disc affects the speed at which it can remove material. A 29 flap disc generally has a higher material removal rate compared to a 27 flap disc. This makes it a more efficient choice for heavy-duty tasks or when you need to remove material rapidly. On the other hand, a 27 flap disc is better suited for tasks that require more precision and control.

Versatility

Both 27 and 29 flap discs offer versatility. However, 27 flap discs, due to their smaller size, are often preferred for tasks that demand a finer finish or more detailed work. They excel in applications like deburring, surface preparation, and light grinding. Meanwhile, the 29 flap discs are ideal for large-scale material removal, be it in shipyards, construction sites, or industrial manufacturing.

Control and Maneuverability

The size of the flap disc also affects the level of control and maneuverability you have during grinding. Smaller 27 flap discs are easier to handle and provide more precise control over your grinding. This makes them suitable for intricate work or tasks where you need to avoid over-grinding.

Cost and Longevity

In terms of cost, 27 flap discs are often more affordable than their larger counterparts. Additionally, they tend to have a longer lifespan when used for precision tasks, as they wear down more slowly due to their smaller grinding surface.

Choosing the Right One

Ultimately, the choice between a 27 and 29 flap disc depends on the specific requirements of your task. If you need precise control, a fine finish, and detailed work, opt for a 27 flap disc. If rapid material removal or grinding over larger areas is the goal, a 29 flap disc is the way to go. Always consider the nature of your job, the material you’re working on, and the level of precision needed to make the right choice.

In conclusion, while size may seem like a minor detail, it can have a significant impact on the outcome of your grinding and finishing tasks. Understanding the differences between 27 and 29 flap discs allows you to select the right tool for the job, enhancing both your efficiency and the quality of your work.