When it comes to precision cutting in DIY projects, home repairs, or professional applications, a rotary tool equipped with the right cutting disc is indispensable. Cutting discs are versatile attachments that transform your rotary tools into a powerful cutter capable of slicing through various materials with ease. In this blog, we’ll explore the different types of cutting discs available, their uses, and tips for selecting and using them effectively.

Types of Cutting Discs

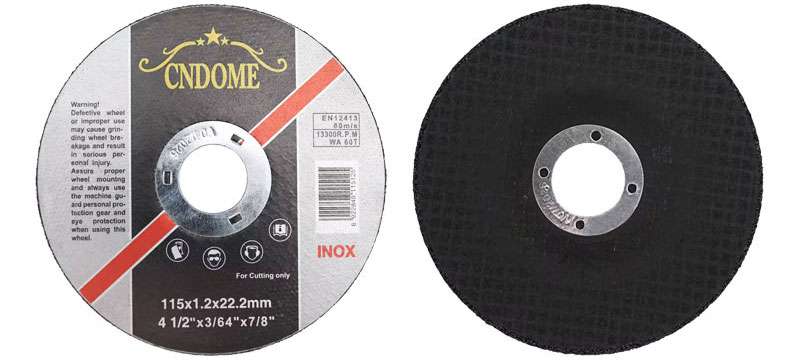

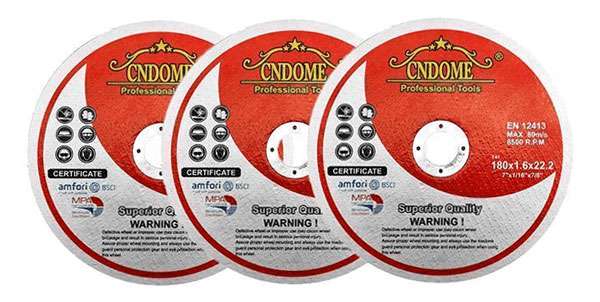

1. Fiberglass Reinforced Cut-Off Wheels:

These are designed for cutting metals and other hard materials. The fiberglass reinforcement provides added strength, allowing these discs to withstand the high-speed rotation of the tool without breaking.

2. Diamond Cutting Discs:

Known for their durability and efficiency, diamond cutting discs are perfect for cutting through tough materials such as glass, ceramics, and stone. The diamond grit embedded in the disc ensures a smooth and precise cut.

3. Abrasive Cut-Off Wheels:

Made from abrasive materials like aluminum oxide or silicon carbide, these discs are ideal for cutting through soft metals, plastic, and wood. They are generally less expensive but wear out faster than diamond discs.

4. Carbide Cutting Wheels:

These are excellent for cutting through dense and hard materials. The carbide tips provide a longer lifespan and are suitable for heavy-duty cutting tasks.

Choosing the Right Cutting Disc

Selecting the right cutting disc depends on several factors:

- Material: The primary consideration should be the material you plan to cut. For example, use diamond discs for stone and ceramic, abrasive discs for soft metals and plastic, and fiberglass reinforced discs for harder metals.

- Disc Size: Ensure the disc size is compatible with your rotary tool. Using the correct size prevents damage to the tool and ensures safe operation.

- Thickness: Thicker discs are more durable and suitable for heavy-duty cutting, while thinner discs offer precision for fine cuts.

Using Cutting Discs Safely

Safety is paramount when using cutting discs with a rotary tool. Here are some key safety tips:

- Wear Protective Gear: Always wear safety goggles, gloves, and a dust mask to protect against flying debris and dust.

- Secure Your Workpiece: Ensure the material you are cutting is securely clamped to prevent movement.

- Proper Tool Handling: Hold the rotary tool firmly and maintain a steady hand to avoid slipping. Let the tool do the work and don’t apply excessive force.

- Check Disc Condition: Before use, inspect the cutting disc for any signs of damage or wear. Replace discs that are cracked or excessively worn.

Tips for Effective Cutting

- Right Speed: Adjust the speed of your rotary tool based on the material being cut. High speeds are suitable for soft materials, while lower speeds work better for harder materials.

- Cooling: For prolonged cutting sessions, especially with metals, periodically let the tool cool down to prevent overheating.

- Angle and Pressure: Keep the disc at the correct angle to the material (usually 90 degrees) and apply consistent, gentle pressure. This approach ensures a clean cut and prolongs the life of the disc.

Conclusion

Cutting discs for rotary tools are essential accessories that enhance the functionality of your tool, making it capable of tackling a variety of cutting tasks with precision and ease. By understanding the different types of cutting discs, selecting the right one for your needs, and following safe usage practices, you can achieve professional-quality results in your projects. Whether you’re a hobbyist or a professional, mastering the use of cutting discs will expand your capabilities and improve the quality of your work.