In the world of metalworking, fabrication, and construction, grinding wheels are indispensable tools. They are designed to perform an array of tasks, from shaping and sharpening to polishing and finishing. However, like any tool, grinding discs come with their own set of advantages and disadvantages. In this blog post, we’ll explore these pros and cons to help you make informed decisions when using grinding wheels.

Advantages of Grinding Wheels

1. Precision and Accuracy:

Grinding discs are renowned for their precision and accuracy. They can remove material with remarkable consistency, making them ideal for applications that demand exacting tolerances and a smooth surface finish.

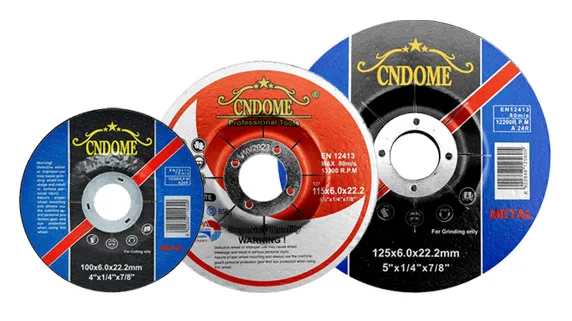

2. Versatility:

Grinding wheels come in various shapes and sizes, each tailored to specific tasks. This versatility allows them to be used in a wide range of applications, from sharpening tools to grinding metal and concrete.

3. Efficiency:

Grinding wheels are efficient cutting tools. Their ability to remove material quickly minimizes downtime and boosts productivity. In industrial settings, this efficiency can result in significant time and cost savings.

4. Durability:

Well-constructed grinding discs can be incredibly durable. They are designed to withstand the demands of rigorous grinding, reducing the need for frequent replacements and saving money in the long run.

5. Flexibility:

Grinding wheels can be used on a variety of materials, including metals, ceramics, stone, and more. This adaptability ensures that they remain an essential tool in various industries.

Disadvantages of Grinding Wheels

1. Safety Concerns:

Grinding wheels can be hazardous if not used properly. The high-speed rotation can cause wheel breakage, leading to flying debris and potential injuries. It is crucial to follow safety guidelines rigorously.

2. Heat Generation:

Grinding generates heat, and excessive heat can lead to material damage or premature wear of the wheel. Proper cooling mechanisms or intermittent grinding may be necessary to mitigate this issue.

3. Dust and Debris:

Grinding operations generate a significant amount of dust and debris. This can pose health risks for workers, and it’s essential to use proper dust extraction systems and personal protective equipment.

4. Noise:

Grinding discs can be noisy, which can be both disruptive and damaging to hearing if adequate protection is not used. Ear protection is often necessary when working with grinding discs for extended periods.

5. Wheel Wear:

Grinding wheels wear down over time, resulting in a decrease in cutting efficiency. This wear requires regular maintenance or replacement, incurring additional costs.

In conclusion, grinding discs are indispensable tools in various industries, offering precision, versatility, and efficiency. However, it’s vital to recognize and address their disadvantages, such as safety concerns and maintenance needs. By understanding both the pros and cons, you can harness the full potential of grinding wheels while mitigating risks and challenges, ensuring a safer and more productive work environment.

Online Message

Minimum Order Quantity: 5,000 Pcs, 10 Pcs Free Samples.

Contact Us For More Information!

Tel/WhatsApp

+86 18796960868

[email protected]

Address